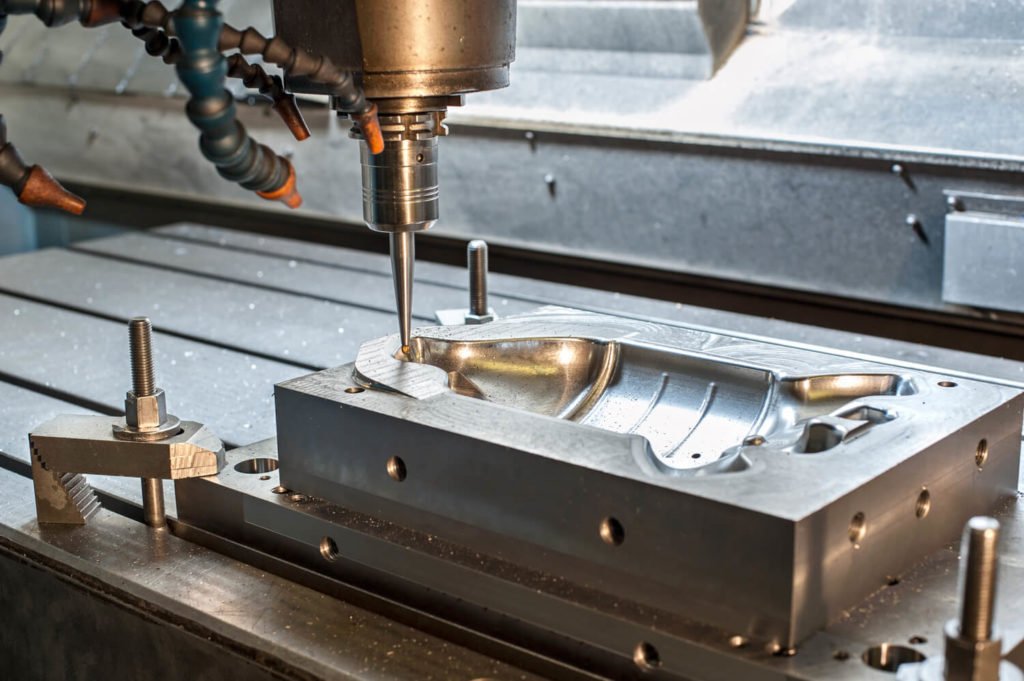

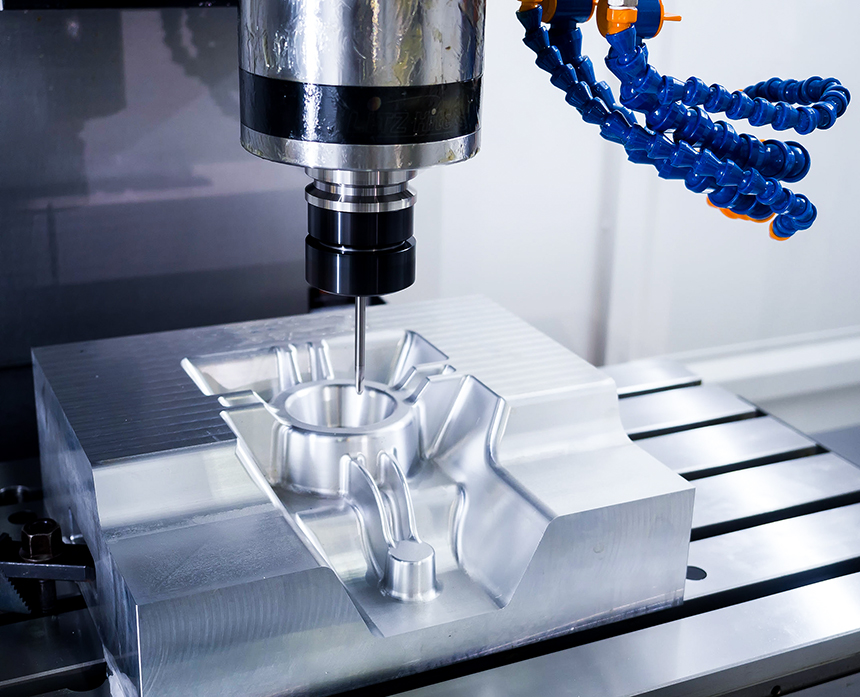

CHẾ TẠO KHUÔN

Thiết kế và chế tạo khuôn theo yêu cầu

Thiết kế khuôn là quá trình tạo ra một bộ khuôn 3D trên máy tính dựa theo những đặc điểm và thông số kỹ thuật của một sản phẩm. Quá trình này có thể áp dụng cho các sản phẩm mới hoặc những sản phẩm cần tạo lại ngoài thực tế.

Để đơn giản hóa công đoạn thiết kế khuôn, bạn có thể sử dụng các phần mềm: Autocad, Catia,… Các phần mềm này sẽ cho phép bạn dựng toàn bộ các chi tiết cần có của một bộ khuôn. Đồng thời, bạn hoàn toàn có thể thể hiện kích thước của các tấm khuôn, ốc xoắn,… một cách chính xác.

Ngoài ra, với những bộ khuôn có kết cấu phức tạp, yêu cầu độ tinh xảo cao thì các kỹ sư sẽ cần thể hiện rõ từng chi tiết nhỏ. Bởi quá trình gia công sẽ khó có thể bao quát được toàn bộ chi tiết. Do đó, những chi tiết nhỏ sẽ rất dễ bị bỏ qua. Điều này sẽ ảnh hưởng trực tiếp đến chất lượng của cả quy trình thiết kế khuôn và tạo hình sản phẩm.

Công ty chúng tôi chuyên về:

- Thiết kế 3D – 2D theo yêu cầu khách hàng

- Lên bản vẻ 2D từ mô hình 3D

- Tạo file 3D từ bản vẽ 2D

- Bóc tách bản vẽ chi tiết từ cụm máy móc

- Thiết kế cải tiến các sản phẩm có sẵn trên thị trường

- Thiết kế máy móc – linh kiện

- Thiết kế khuôn ép nhựa

- Thiết kế khuôn thổi nhựa

- Thiết kế khuôn dập

- Thiết kế cải tiến sản phẩm tối ưu làm khuôn…

Các yêu cầu đạt chuẩn cho một khuôn đúc

Sau các quá trình sản xuất, thử khuôn, xác nhận của khách hàng một khuôn đúc nhựa chất lượng sẽ đạt các yêu cầu về kích thước thiết kế chuẩn, độ chính xác cao, sản phẩn sử dụng không bị hao mòn, kết cấu khuôn đạt chất lượng để sản xuất hàng loạt.

Tại Nhựa Lam Hồng mỗi khuôn sản xuất ra cũng như đưa vào sản xuất hàng loạt luôn được bảo hành, luôn được chăm sóc kĩ càng để đạt được những sản phẩm tốt nhất cho khách hàng

Các quy trình gia công và thiết kế khuôn

- Tiếp nhận yêu cầu và ý tưởng từ khách hàng

- Thiết kế theo yêu cầu của khách hàng, xác nhận về độ chính xác của sản phẩm với khách hàng.

- Tiến hành hoàn tất thiết kế 3D

- Lập trình các quy trình của giai đoạn làm khuôn

- Sau quá trình sản xuất, khuôn sẽ được đánh bóng, lắp ráp và qua quá trình thử khuôn

- Quá trình thử khuôn sản phẩm sẽ qua các lần thử với khách hàng cùng đội QC của công ty để đưa ra khuôn chất lượng nhất đạt đầy đủ yêu cầu khách hàng đưa ra.

- Sau khi hoàn tất thì khuôn đúc nhựa mới được đưa vào sản xuất hàng loạt các sản phẩm với độ chính xác cao nhất.

VINASTAR chúng tôi nhận gia công ép nhựa – giao hàng tận nơi nội địa và quốc tế Với việc VN ngày càng phát triển hạ tầng giao thông.

Các dịch vụ vận chuyển được đa dạng hoá bao gồm đường hàng không, đường bộ và đường biển. Do đó, việc giao hàng trong nước và quốc tế dễ dàng và rẻ hơn rất nhiều. Khách hàng có nhu cầu làm khuôn nhựa trong và ngoài nước vui lòng liên hệ với chúng tôi qua thông tin sau:

THÔNG TIN LIÊN HỆ

Hotline: 0936 116 009

Email: vinastar.ceo@gmail.com

Địa chỉ: Số 637 Đường điện biên phủ, Phường Phú Tân, TP. Thủ Dầu Một, Bình Dương

Website: https://vinastarvn.com/