THIẾT KẾ SẢN PHẨM NHỰA

Dịch vụ thiết kế sản phẩm nhựa theo yêu cầu

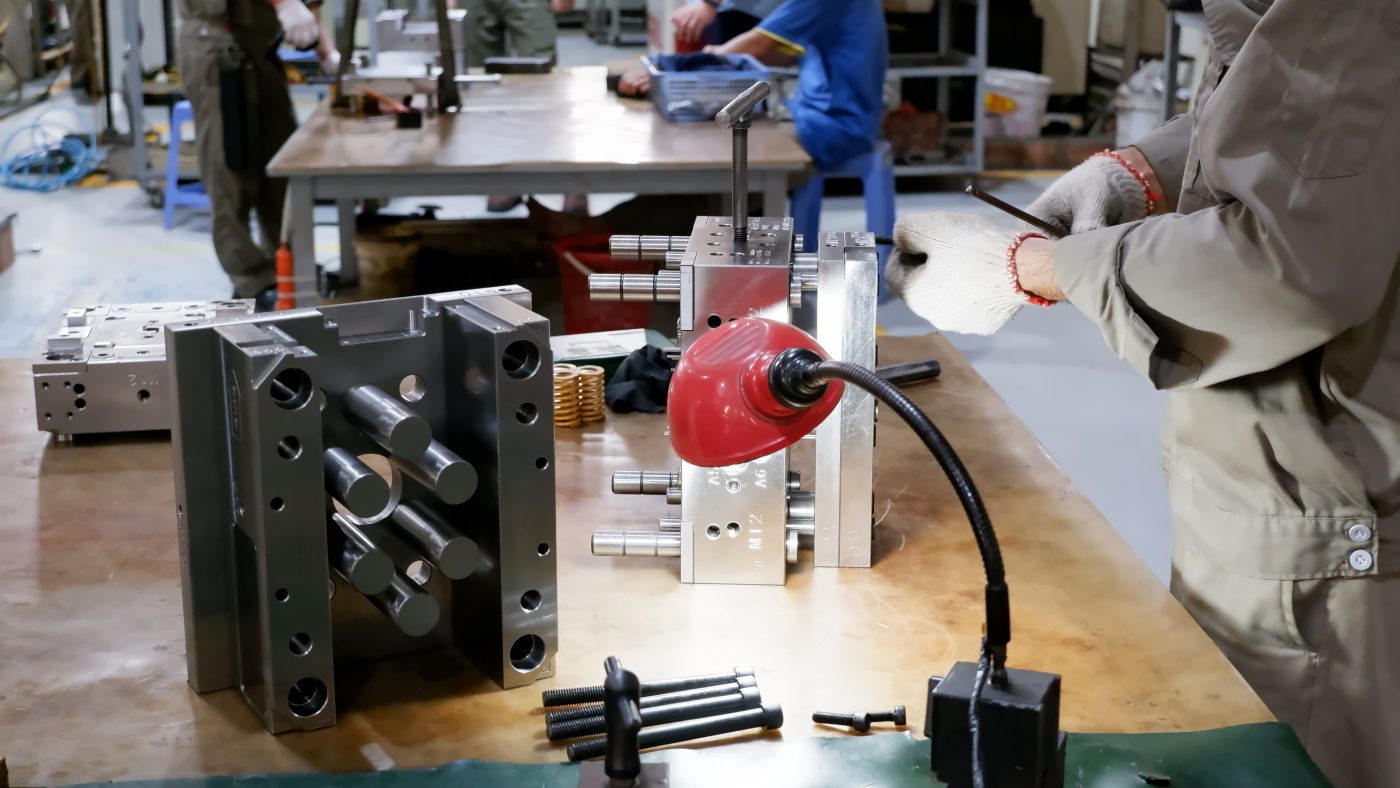

Công ty TNHH Nhựa Lam Hồng là đơn vị chuyên nhận gia công, thiết kế sản phẩm nhựa theo yêu cầu, đồng thời có năng lực gia công ép nhựa chất lượng cao. Nhựa Lam Hồng đáp ứng mọi yêu cầu dù là khắt khe nhất, mang lại sự hài lòng và tin tưởng tuyệt đối cho khách hàng, các đơn vị đối tác.

Những yếu tố cần thiết trong thiết kế sản phẩm nhựa

Công việc thiết kế sản phẩm nhựa, khuôn ép nhựa muốn thực hiện được đòi hỏi công sức của đội ngũ kỹ sư, những người có năng lực chuyên môn, có hiểu biết về thiết kế cơ khí chính xác. Người tham gia thiết kế cần nắm rõ các yêu cầu cụ thể từ phía khách hàng, từ đó xác định được các yếu tố cần thiết của sản phẩm. Căn cứ vào cơ sở vật chất, năng lực của công ty khuôn mẫu, kỹ sư thiết kế đưa ra bản thiết kế tối ưu nhất cho sản phẩm khuôn mẫu khách hàng mong muốn.

Công ty TNHH Nhựa Lam Hồng là đơn vị hàng đầu tại Việt Nam trong thiết kế, chế tạo và cung ứng các sản phẩm khuôn mẫu, cơ khí chính xác kỹ thuật cao. Khách hàng của Nhựa Lam Hồng sẽ được tư vấn một cách cụ thể, kỹ càng nhất để cuối cùng thống nhất phương án sản xuất, cho ra đời sản phẩm khuôn mẫu chất lượng, giá cả cạnh tranh.

- Tiết kiệm chi phí gia công khuôn mẫu, nhờ việc tối ưu hóa cấu tạo.

- Chon loại vật liệu nhựa phù hợp nhất, giúp tiết kiệm chi phí, nâng cao chất lượng sản phẩm.

- Rút ngắn thời gian thực hiện của mỗi chu kỳ ép phun, tăng cao năng suất.

- Giảm thiểu đáng kể các lỗi của sản phẩm tạo thành như cong, vênh, bavia…

Công ty Nhựa Lam Hồng luôn không ngừng trăn trở, tối ưu hóa quy trình thiết kế sản phẩm nhựa, cung cấp tới khách hàng sản phẩm tốt nhất, đáp ứng yêu cầu kỹ thuật được đặt ra.

Dịch vụ thiết kế sản phẩm nhựa bao gồm:

- Nhận thiết kế mọi loại sản phẩm nhựa theo yêu cầu

- Thiết kế sản phẩm đơn lẻ và sản phẩm theo bộ hoàn chỉnh

- Tối ưu thiết kế để giảm chi phí cho công đoạn chế tạo – sản xuất

- Thiết kế cải tiến theo mẫu có sẵn và theo ý tưởng mới

- Tư vấn miễn phí – hỗ trợ từ đầu công đoạn sản xuất thành phẩm

- Xuất file 2D – 3D mọi định dạng (.igs, .step, .slt, .xt,…)

Nhựa Lam Hồng nhận thiết kế sản phẩm nhựa theo sản phẩm có sẵn

Hiện nay, ngày càng nhiều khách hàng có mong muốn được xây dựng thiết kế sản phẩm nhựa, thiết kế khuôn mẫu từ những đồ dùng nhựa có sẵn. Nhiều khách hàng mong muốn có được sản phẩm với chất lượng và tính thẩm mỹ vượt trội so với những sản phẩm mẫu.

Lúc này, đội ngũ kỹ sư sẽ tiến hành chụp hình 3D sản phẩm mẫu, từ đó thực hiện đánh giá, phân tích từng chi tiết và cho ra đời bản thiết kế 2D, 3D.

Bên cạnh đó, việc đánh giá đặc điểm, tính chất, sự phù hợp của vật liệu nhựa là thật sự cần thiết, là cơ sở để lựa chọn loại vật liệu nhựa mới tốt hơn, góp phần nâng cao chất lượng sản phẩm, tiết kiệm chi phí sản xuất.

Với tâm huyết của đội ngũ kỹ sư, bản thiết kế sản phẩm nhựa mới được hoàn thiện, phục vụ tốt cho quá trình chế tạo khuôn mẫu. Các sản phẩm nhựa mới ra đời có kiểu dáng giống hệt sản phẩm mẫu ban đầu và có thể mang lại các đặc điểm ưu việt hơn rất nhiều.

Lam Hồng nhận gia công, thiết kế sản phẩm nhựa đa dạng theo yêu cầu

Nhựa Lam Hồng có thể đáp ứng một cách đa dạng nhu cầu thiết kế sản phẩm nhựa theo yêu cầu của khách hàng, ngay cả trong trường hợp khách hàng chỉ cung cấp ý tưởng.

Đội ngũ chuyên gia sẽ tư vấn một cách cẩn thận, rõ ràng cho khách hàng về đặc tính của sản phẩm, những đòi hỏi trong quá trình gia công chế tạo để cho ra đời sản phẩm nhựa tốt nhất với giá thành hạ. Việc gia công, chế tạo các loại sản phẩm nhựa hiện đại đòi hỏi đơn vị gia công cần có cơ sở vật chất, trang thiết bị máy móc, các phần mềm thiết kế hiện đại, đội ngũ nhân lực trình độ cao, công nhân lành nghề.

Công ty Cổ phần Việt Chuẩn hoàn toàn tự tin với năng lực sản xuất của mình, sẽ nhanh cung cấp tới khách hàng bản thiết kế chi tiết sản phẩm nhựa, thực hiện gia công nhanh chóng, chính xác và tiết kiệm.

VINASTAR chúng tôi nhận gia công ép nhựa – giao hàng tận nơi nội địa và quốc tế Với việc VN ngày càng phát triển hạ tầng giao thông. Các dịch vụ vận chuyển được đa dạng hoá bao gồm đường hàng không, đường bộ và đường biển.

Do đó, việc giao hàng trong nước và quốc tế dễ dàng và rẻ hơn rất nhiều. Khách hàng có nhu cầu làm khuôn nhựa trong và ngoài nước vui lòng liên hệ với chúng tôi qua thông tin sau:

THÔNG TIN LIÊN HỆ

Hotline: 0936 116 009

Email: vinastar.ceo@gmail.com

Địa chỉ: Số 637 Đường điện biên phủ, Phường Phú Tân, TP. Thủ Dầu Một, Bình Dương

Website: https://vinastarvn.com/