MANUFACTURING AND PROCESSING PLASTIC PRODUCTS

Production and processing of plastic products on demand

Plastic products have penetrated every corner and field of life. Therefore, the demand for production and processing of plastic on demand from suppliers, plastic agents, garment companies, factories, manufacturing plants, etc. is extremely large. This is the most optimal solution because it meets the needs of sales and use. It also saves costs.

Known as one of the units specializing in processing and manufacturing plastic products on demand. Lam Hong Plastic Company brings to businesses, partners, and customers plastic processing services on demand with the lowest production costs. While still ensuring high product quality because it is produced 100% from imported virgin plastic particles.

Why should you hire custom plastic processing?

Pre-Production Process

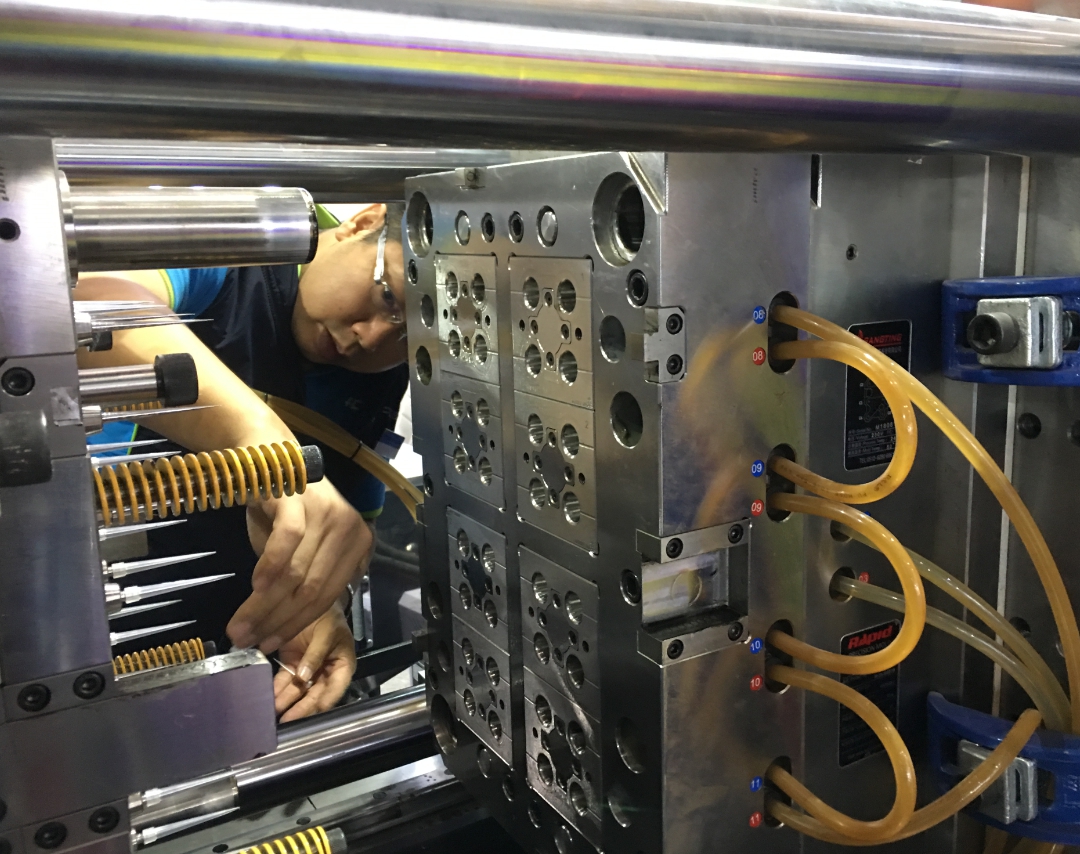

Plastic injection mold design and manufacturing

Based on the design requirements, we strategize the quantity and sequence of optimal plastic injection mold design processes, and build a closed production process. Thermoforming, vacuum forming, CNC manufacturing and many other plastic production processes are involved in this stage. This process takes the most time, and is also a very important step, so customers need to be patient and work with us so that the finished product is the most standard and optimal.

Post-production process

In the post-production process, we provide a link service to accompany customers in product warranty. This is the final step of the plastic production contract, which is packaging, shipping and delivery to the agreed location with you. We ensure that the products are well packaged, economical, safe and delivered within a specific time frame without any interruptions.